CNC Machining

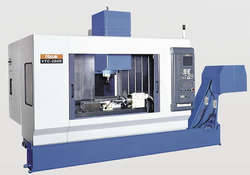

Applied Automation houses four large CNC Machining Centre's, two Mazak VTC200B's, a Mazak FJV-250-II and a Mazak j-500 Variaxis allowing us to produce a high output of precisely engineered parts.

The Mazak VTC-200B is a vertical machining centre featuring Mazatrol control, bar capacity, chuck size, and 10,000 RPMspeed. Mazak's VTC-200B's offers unidirectional positioning accuracy of ±0.0002" and unidirectional repeatability of ±0.0006".

The Mazak FJV-250 II is a high-precision, high-productivity, double-column Vertical Machining Centre. The special double-column provides enhanced performance for extremely high precision machining even over extended periods of operation.

The Mazak Variaxis j-500 offers cost-effective and efficient multi-surface part machining. This vertical machining centre allows single-setup processing through fast, high rigidity spindles and high accuracy rotary/tilt table. Eliminating multiple setups provides large reductions in total production times, whilst still producing improved component accuracy.

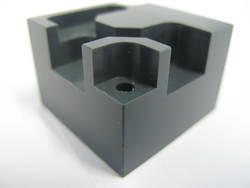

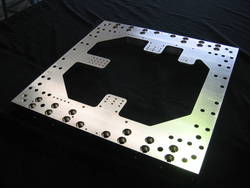

With our vast experience and extensive equipment we can manufacture many different materials types such as plastics, aluminium and steels.